Description

Specifications of Flat Die Thread Rolling Machine:

| Model(High Speed) | Shank Diameter MM | Shank Length MM | Output PPM | Main Motor KW | Weight KG |

| ARH-4 | 1-4 | 40 | 200-240 | 1.5 | 1000 |

| ARH-6 | 3-6 | 50/70/105 | 160-200 | 4 | 1850 |

| ARH-8 | 4-8 | 80/105/150 | 140-160 | 5.5 | 2350 |

| ARH-10 | 6-10 | 105/150 | 120-145 | 5.5 | 3850 |

| ARH-12 | 8-12 | 105/150 | 80-100 | 15 | 6200 |

| ARH-16 | 12-16 | 100/150/200 | 55-65 | 22 | 6950 |

| ARH-20 | 12-20 | 150/300 | 45-50 | 30 | 13800 |

| ARH-24 | 16-24 | 150/300 | 30-45 | 45 | 18000 |

| ARH-30 | 24-30 | 150/300 | 30-40 | 55 | 23000 |

| Model(Normal Speed) | Shank Diameter MM | Shank Length MM | Output PPM | Main Motor KW | Weight KG |

| ARN-6 | 3-6 | 50/70/105 | 80 | 2.2 | 600 |

| ARN-8 | 4-8 | 80/105/150 | 75 | 4 | 800 |

| ARN-10 | 6-10 | 105/150 | 70 | 5.5 | 1200 |

| ARN-12 | 8-12 | 105/150 | 60 | 7.5 | 1500 |

| ARN-16 | 12-16 | 100/150/200 | 50 | 15 | 3000 |

| ARN-20 | 12-20 | 150/300 | 40 | 18.5 | 5000 |

| ARN-24 | 16-24 | 150/300 | 35 | 22 | 8000 |

| ARN-30 | 24-30 | 150/300 | 30 | 30 | 10000 |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

Application Scope of Flat Die Thread Rolling Machine

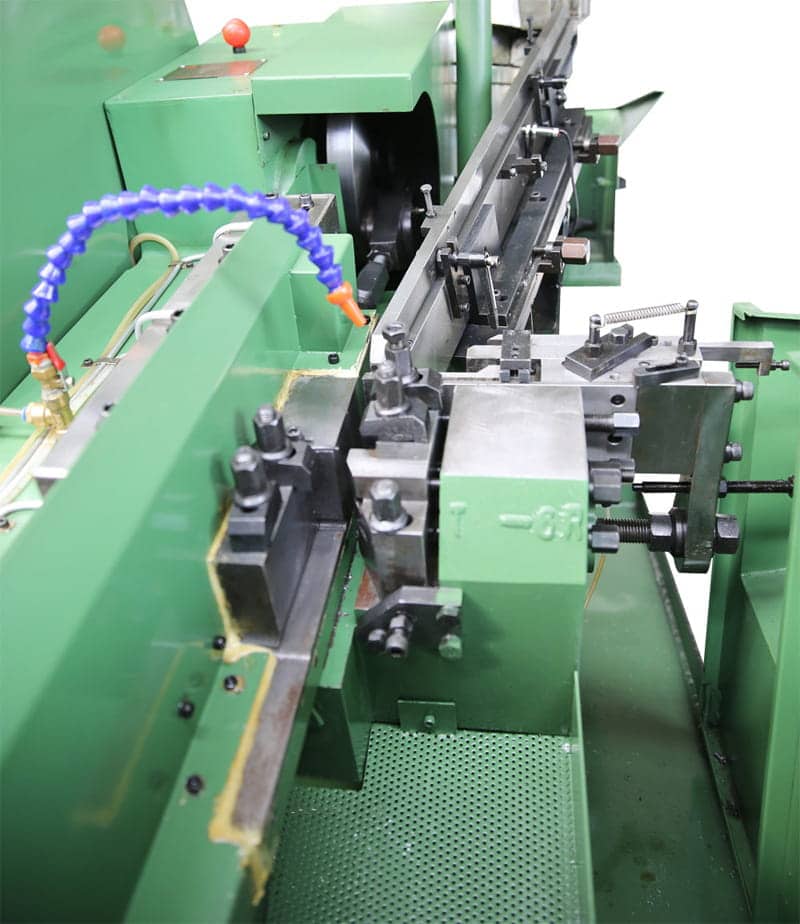

Flat Die Thread Rolling Machine is a kind of machine with two-parallel thread rolling dies to reciprocate the thread of various screws and bolts, which is an automatic device without chip processing. The production screws and bolts thread rolling process achieved by subjecting the workpiece to cold forming extrusion. The machine tool has a stable and powerful manufacturing force, and the unique material pushing mechanism design makes the workpiece feeding smoothly. The centralized lubrication system ensures that the friction part can be lubricated in the oil film to ensure the durability of the machine. Our company has a variety of full automatic, semi-automatic, manual feeding three types of Flat Die Thread Rolling Machine to be selected, material loading have vibration hopper type, multi-function board layer hopper, single board layer hopper, drum type for users to choose, and can be customized according to user’s products and requirements.

Items can be threading by Flat Die Thread Rolling Machine

self tapping screws,rivets,hinge pin and special parts,chipboard screw,particle board screw,double ended screw,dowel screw,hanger bolt,drywall screw,lag screw,mirror screw,sheet metal screw,Twinfast screw,wood screw,Security head screw,self-drilling screw,self-tapping machine screw,Teks screw,auto fasteners,etc.

Salient Features of Flat Die Thread Rolling Machine

1.The high speed screw thread rolling machine machine is a professional production of screw equipment

2. The high speed screw thread rolling machine adopts two reeling boards to roll threads on various screw heads of the head. The threading accuracy can reach two grades. It is suitable for mass production of fasteners and other knurled workpieces.

3.This machine adopts the cold forging method, suitable for the production of a variety of screws, wood screws, internal hexagonal, concave hex rivets machine tool processing. The machine can automatically complete the feeding, straightening, cutting, forming, and forging.

4.The high speed screw thread rolling machine is an economical and efficient multi-function cold roll forming machine.

5.The machine features: low input, high output, easy operation, stable performance, wide applicability and easy maintenance. The machine can perform threading on the workpiece in the cold state within the range of its rolling pressure. Straightening, straight teeth, knurling and other forms of rolling processing. Cold rolling process is an advanced non-cutting process, which can effectively improve the internal and surface quality of the workpiece. It is an ideal product with high efficiency, energy saving and low consumption.