Description

Automatic CNC Servo Feeding Tube Circular Sawing Machine

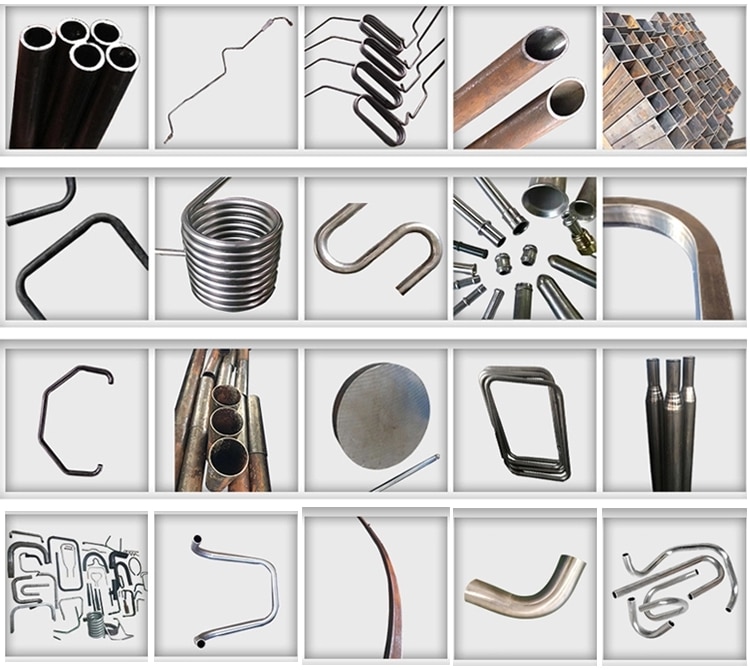

Adapted material:Cut to length of steel pipe, stainless steel tube, copper pipe, aluminum pipe,etc.

Recommended application industry:

automobile fittings ( oil pipe for brake, muffler, seats), motorcycle, healthy equipment, air-conditioning,bicycle, steel furniture, sanitary wares and so on

Main chararteristics

(1) Controlled by hydraulic system

(2) Automatic cooling system

(3) Automatic clamping the pipe

(4) Automatic cutting the pipe

(5) No row edge

(6) No noise

(7) High efficiency and accuracy

(8) Suit to heavy duty cutting

(9) Durable saw blades

(10) Automatic feeding of pipe

(11)It can set the feeding length,you only need to change the parameter in machine’s computer when you want to change the cutting length.

(12) Long life of saw blades. The saw bladws is special designed.

(13) It can cut several pieces of pipes at the same time.

Technical parameter

| Specification/Model | AMC-350CNC | ||

| sawing scale | Applicable sawblade Ф250-Ф400 | ||

| rectangle pipe | 120mm x 90mm | ||

| square pipe | 110mm×110mm | ||

| round pipe | Φ110mm | ||

| round bar | Φ75mm | ||

| square bar | 65mm×65mm | ||

| Size | 1600×1850mm×1600mm | ||

| Weight | 800kg | ||

| Main motor(KW) | 3.5-4.0KW | ||

| Main shaft speed(RPM) | 88/44 | ||

| Feeding length Standard | 5-700mm*time after time | ||

| Oil motor system | 3.5KW motor,18L pump | ||

| Cooling system | 0.09KW motor | ||