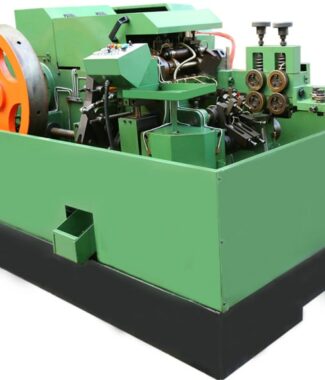

Description

Running video of ABM-5 Bi-metallic contact rivets cold heading machine

APPLICATION OF THE ABM-5 Bi-metallic contact rivets cold heading machine

• MICRO SWITCH MANUFACTURERS

• AUXILIARY SWITCH MANUFACTURERS

• ROTARY SWITCH MANUFACTURERS

• LIMIT SWITCH MANUFACTURERS

• KNIFE SWITCH MANUFACTURERS

• ROCKER SWITCH MANUFACTURERS

• DOMESTIC SWITCH MANUFACTURERS

• AUTOMOTIVE SWITCH MANUFACTURERS

• RELAYS MANUFACTURERS

• MOTOR STARTER

• SWITCH GEARS MANUFACTURES

• AUTOMOTIVE MANUFACTURES

• AVIATION MANUFACTURES

• APPLIANCES MANUFACTURES

The ABM-5 Bi-metallic contact rivets cold heading machine can produce cold headed solid and bimetal contacts from a wide variety of materials.

Typical alloys include:

- Silver

- Fine grained silver

- Silver-Nickel

- Silver-Iron

- Silver-Graphite

- Silver-Cadmium Oxide

- Silver-Tin Oxide

- Gold

- Platinum

- Palladium

Main Technical Parameters of ABM-5 Bi-metallic contact rivets cold heading machine

| NO. |

Item |

Unit |

Data |

|

1 |

Power of the motor |

KW |

2.2 |

|

2 |

Shear intensity |

Mpa |

≥ 98 |

|

3 |

Weight of the machine |

Kg |

1100 |

|

4 |

Diameter of the rivet’s head |

mm |

2.5-6 |

|

5 |

Diameter of the rivet’s shank |

mm |

1.2-3 |

|

6 |

Diameter of the plate product |

mm |

3-6 |

|

7 |

Output |

pcs/min |

0-130 |