Description

Double Ends Station Pipe End Forming Machine

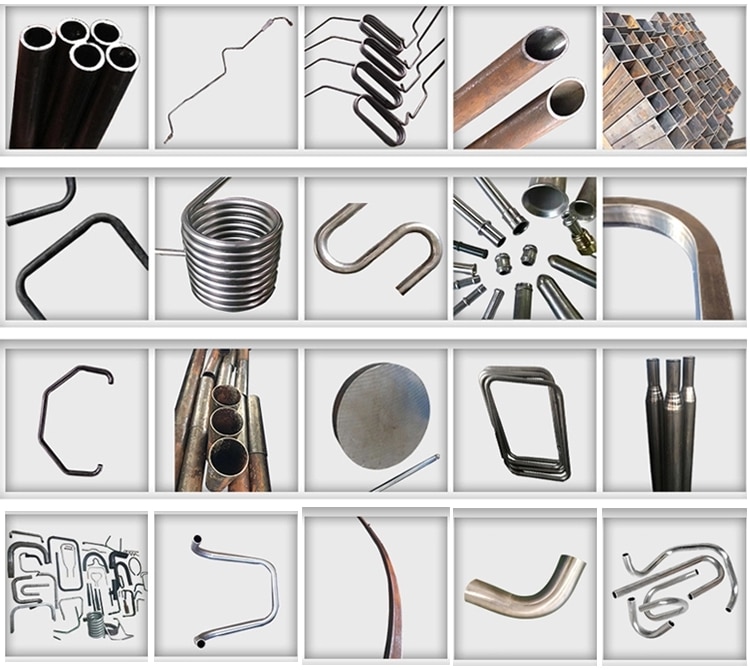

Adapted material:

steel pipe, stainless steel, copper pipe, aluminum pipe etc.

Main specification

1) NC Control Unit: Easy Operation and Maintenance

2) Suitable for the shrinking of various metal pipes with different material and different shape

3) Equipped with emergency stop device. Both manual and automatic operations are available

4) Shrinking stroke 100mm. The max. workpiece length is 450mm, with no minimum workpiece length

5) Forming shapes can be convex, concave, sectional, long 7 flat, square, V-shaped, open elbow and flat elbow. The design of the tooling varies with workpiece and customers’ requirements

Technical parameter

| Type | ASG-40 | ASG-60 | ASG-80 | ASG-100 |

| Max tube(mm) | φ40*2.0 | φ60*2.0 | φ80*3.0 | φ100*3.5 |

| Max processing length(mm) | 110 | 130 | 150 | 180 |

| Oil pressure(Mpa) | 14 | 14 | 14 | 14 |

| Working speed | 100mm in3-4/s | 100mm in3-4/s | 100mm in3-4/s | 100mm in3-4/s |

| Size(cm) | 180*45*120 | 200*50*130 | 290*70*140 | 300*75*150 |

| Weight(kg) | 600 | 950 | 1600 | 1800 |

| Remark | 1.The max processing length can according to customers requirement. | |||